NHK did a documentary special of Fukushima I Nuclear Power Plant for the second anniversary of the nuclear accident. It sent reporters to the plant, and also did its own analysis and simulation experiments with the help of experts.

NHK says it obtained the blueprints of Reactor 3, and carefully studied them with the experts. Now why wouldn't anyone have done it sooner?

The news below must be a segment from the documentary. NHK raises the possibility that Reactor 3's meltdown occurred because not enough water was reaching the Reactor Pressure Vessel, and more than half the water being injected by the fire engines went to the condenser instead.

The pump that circulates the water from the condenser had a line coming in from the main water line to the Reactor Pressure Vessel. In normal condition, the powerful pump (2,500 tonnes/hour) prevents any water coming in from the line as its blades spin at a very high speed. However, the pump stopped on March 11, 2011 when the power was totally lost. So the water injected into the main water line to the RPV reached the condenser pump and went to fill the condenser, instead of going to the RPV.

NHK also says if the loss was only 25% of water instead of 55%, the meltdown may not have happened.

TEPCO did mention in a press conference in the very early days of the nuclear accident that for some reason the condensers in Reactor 2 and Reactor 3 seemed to be full of water. In those days, reporters probably didn't even know what a condenser in a nuclear power plant was, and TEPCO's managers (they were engineers in the beginning of the accident) couldn't explain things well to the general public.

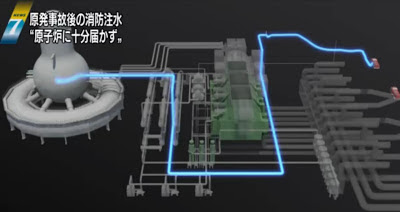

Screen captures from NHK News (3/10/2013):

Experts examine the blueprints for Reactor 3, and they notice the water line from the fire engine to the reactor is connected to a line that could divert the water to the condenser:

Fire engine pumping water into the water line that reaches the Reactor:

But this line has a small feeder line to the Condenser Unit:

The pump is installed there to regulate the flow of water:

The water from this feeder line does not flow to the Condenser Unit in the normal condition (i.e. the pump is powered by electricity):

But when the power was lost, the pump stopped, and the blades stopped spinning, and there was nothing to stop the water being injected by the fire engine from going into the Condenser Unit.

TEPCO did mention the Condenser Units of Reactor 2 and Reactor 3 to be full of water, in a press conference in 2011 right after the start of the accident:

So NHK and the experts NHK consulted do a simulation, using a small-scale model, and conclude that about 55% of water injected may have leaked into the Condenser Unit.

They further conclude that if the leak was up to 25% of the water injected, the meltdown may have been prevented:

Then, NHK turns to fire engines installed at nuclear power plants after the Fukushima accident, and says "Nobody knows whether a sufficient amount of water from a fire engine can reach the reactor in an emergency."

One of the experts comments, "It is a mistake to feel safe, or secure, just because you have fire engines on site."

I remember experts commenting that the pressure from heating fuel inside the Pressure Vessel prevented enough water from reaching the Pressure Vessel. I wonder if they knew about the line to the condenser pump, or if it occurred to them that the water intended for the Pressure Vessel got diverted to the condenser because of the loss of power to the pump.

=========================================

Original Japanese NHK News, which has additional information that does not appear in the news video:

3号機に注水の半分以上漏出か

東京電力福島第一原子力発電所の事故で、1号機に続いてメルトダウンした3号機について、当時、消防車から緊急に原子炉に向けて注入した水の半分以上が、別の装置に漏れ出し、冷却に必要な量の水が原子炉に入っていなかった可能性の高いことが、NHKが専門家と共に行った解析や実験で分かりました。

消防車は、事故のあと、安全対策の要として全国の原発に配備されていますが、原子炉に確実に水が入るのか、事故から2年になる今も十分な検証が進んでいない実態が浮かび上がりました。

おととし3月の福島第一原発の事故では、1号機から3号機まで次々にメルトダウンし、建屋が水素爆発するなどして、大量の放射性物質が外部に放出されました。

事故から2年、なぜメルトダウンを防げなかったのか、十分な解明が進まないなか、NHKは、当時緊急に行われた消防車からの原子炉への注水に注目し、なすすべなく最初に水素爆発した1号機のあとに危機を迎えた3号機で検証しました。

消防車による注水を巡っては、一部が原子炉以外のどこかに漏れているのではないかという指摘が専門家からあり、NHKは、独自に入手した3号機の配管の図面などを基に、専門家と共に詳しく分析しました。

その結果、消防車から原子炉までの配管ラインの途中に水の抜け道があり、ここを通って、原子炉とは別の装置に水が漏れ出る可能性のあることを見つけました。

この抜け道の先には、発電に使われた蒸気を再び水に戻す「復水器」と呼ばれる装置があり、通常はその途中にあるポンプが動いていて水がせき止められるため、復水器に水が流れ込むことはありません。

ところが、専門家の協力を得て実験すると、ポンプが止まった場合、素通りして水が先に流れることが分かり、すべての電源を失った福島の事故の際には復水器側に水が漏れ出る可能性が高いことが分かりました。

当時、3号機の復水器は通常ではあり得ない満水状態だったことが、事故直後に東京電力が行った記者会見で明らかにされていて、今回の実験結果を裏付けています。

さらに、消防注水した際の当時の3号機の水の流れを実験で再現し、その結果を基に専門家が解析すると、原子炉に入らずに漏れた量はおよそ55%に上り、この量ではメルトダウンを防げなかったという結果になりました。

一方、漏れた量が25%までなら、メルトダウンは防げるという結果になっています。

消防車は、事故のあと、安全対策の要として全国の原発に配備されましたが、原子炉に確実に水が入るのか、事故から2年になる今も十分な検証が進んでいない実態が浮かび上がりました。

法政大学の宮野廣客員教授は、「消防車を配備すれば終わりではなく、本当に核燃料を冷やすのに十分な量の水が入るのかを確かめなければ、意味がない。事故の検証は不十分だ」と指摘しています。

「放射性物質漏らさない」構造が落とし穴に

原子炉に向けて注水した水がポンプから復水器に漏れ出した背景には、放射性物質を外に漏らしてはいけないという、原発特有の“落とし穴”がありました。

水が漏れる原因となった、「復水器」につながるポンプは、1時間に2500トン近くの水を送り出す能力があり、猛スピードで回転するため、通常、軸の部分に少量の水を送り込んで熱の発生を抑える工夫が凝らされています。

一般のポンプであれば、水は送り込んだあと、そのまま外に排出しますが、原発で使うポンプの場合、放射性物質を含む水を外に漏らしてはいけないため、水でふたをする「封水」と呼ばれる特殊な構造をしています。

「封水」は、ポンプの羽根が回転する際に発生する水の圧力によって、ポンプに流れ込む水をせき止めます。

ところが、福島の事故では、すべての電源が失われてポンプが止まってしまったため、ポンプを素通りして、復水器に水が流れました。

緊急時に原子炉に注水する際、本来、水の漏れがあってはいけません。

ポンプの構造に詳しい東京海洋大学の刑部真弘教授は、「原発のように汚染水を絶対に漏らしてはならない状況では非常によくできた仕組みだが、電源が失われた今回は、大きな盲点になった。似たようなケースはほかにもある可能性があり、どこに弱点が存在するのか、徹底的に検証すべきだ」と指摘しています。

原子力規制委はまだ検証できず

消防車を使った原子炉への注水の検証が十分進んでいないことについて、国の原子力規制委員会で、原発の新安全基準作りを担当している更田委員に聞きました。

更田委員は「当然、漏れることは考えられるし、消防車やポンプ車で期待した量がすべて原子炉にいくわけではないと考えてもらっていい。安全基準や注水の手順で足りないところを見つけることは、事業者と個別の原子炉を対象に図面を基に議論しようとしているが、今の時点ではほとんどやっていない」と述べ、現状では規制委員会としても検証ができていないことを認めました。

そのうえで、今後の対応について更田委員は、「弱点探しや、実際に事故が起きたときにどうしようかという議論は、基準とは別の話だ。消防車による代替注水で十分な能力なのか、十分な手順なのか、万一事故が起きたときに実際に対応する人たちと私たちが向かい合って議論することになると思う」と述べ、消防車による注水のように、事故が起きたときの対応については、安全基準とは別に、事業者と直接議論をして対応策を検討する考えを示しました。

Tokyo Time

Tokyo Time

![[Most Recent Quotes from www.kitco.com]](http://www.kitconet.com/charts/metals/gold/t24_au_en_usoz_2.gif)

9 comments:

NHK has broadcast several excellent documentaries during the last two years about Fukushima, I almost feel like paying the license fee.

My understanding is that this pump is a very fundamental component of every power plant, not just nuclear ones: plants generate steam to operate the turbines that produce electricity; after exiting the turbines the steam is cooled down until it becomes water (in the condenser) and finally this water needs to be pumped back where the steam is generated, in order to repeat the cycle. This is the job of the pump at hand, I believe. If Tepco employees forgot the very existence of such a pump it is really gross.

Or did they forget that cooling water (which is radioactive) is recirculated? Hmmm... And all the three commissions that looked at the accident also overlooked this? Or simply they chose not to hear what the experts NHK talked to were saying? Impressive.

Beppe

Thank you for this article pointing out another deception of the nuclear industry, LaPrimavera!

These findings are not only important for the Japanese nclear plants, but for all water-cooled reactors in the world.

Water often takes other paths than anticipated. This was also the reason for Germany's first commercial nuclear plant's large accident (Gundremmingen 1977), which led to its decommissioning.

It should be normal at an industrial complex of that size and risk to have a fire brigade with a few fire trucks ready.

And this matter of common sense is now praised as a "solution".

It's a placebo solution.

Fascinating. One would expect check-valves... but apparently not.

Well, using fire trucks was improvised, feeding water through that line was improvised.

I appreciate the creativity of the Tepco staff that possibly averted an even worse disaster but still the outcome of the event was totally based on luck; Daini had slightly better luck and so we only experienced 3 meltdowns. Good luck with the restarts.

Beppe

Beppe, you are wrong in your assessment. There was no such innovation there. The piping needed to be able to inject water from fire trucks into the reactors had been already installed (I want to say in 2002, but I don't really recall) and the possibility taken into account in accident guidelines, or else it would have been, quite simply, impossible to implement.

@2:10 Well, then how come half of the water went the wrong way and they realize what happened only two years later? Point taken that the piping was not there by chance but did they ever test it? or did they test it while the pump was in operation (electricity available and everything)? Or did they forget to operate some valve during the disaster?

As it stands, the maneuvre still looks either improvised or, worse, a carried out without any professionalism -- and with F2 we have just been really, really lucky.

Beppe

Beppe, looking at other nuclear power plants, that inlet for fire hose is built-in. As for testing it while the pump was in operation, I don't think they can do that in a plant that is operating normally. You CANNOT stop the pump without mixing up the radioactive water.

As to plugging the pipe after they realized (if they did) what was happening, it may not have been possible to do so. The pipe is in the turbine building. I don't know which floor it is located, but it may not have been easily accessible after the earthquake/tsunami and Unit 1 explosion.

It is also very possible that TEPCO didn't know the details of how different pipes run. They are operator of the plant in the peacetime, not the builder.

You seem to want to blame everything on TEPCO and get easy on the government. I'm afraid to think what the plant would be now if it had been up to the government to do anything.

@1:05 Well, Tepco did not know what was happening: the technician in Primavera-san post is admitting that. Also, this story is surfacing two years later so either they need NHK to tell them how to operate a npp or this is the n-th coverup. Either way this is not tolerable in case of a nuclear powerplant.

Another possibility is that these fire hose inlets are like the other safety features of npps: a pathetic joke. They have redundant power lines but, oops, an earthquake can easily knock all of them out. They have emergency generators but, oops, a flooding can knock them out too. They have batteries but, oops, half are lost upfront and the others run out in a matters of hours. They have containment but, just in case, with a hole to vent out the shit (without filters of course) and anyways it leaks. And on and on.

I am not saying that the government bureaucrats would have operated the plant better, it is not their job anyways. My problem is that it seems that utilities can not operate them well either and I suspect that the problem is partly with the utilities but mainly with the idea of nuclear generation itself: in practice it is just too risky. In fact, it is so risky that General Electric is pulling out of the nuclear business in India because they might be held fully liable in case of a disaster (see recent article on Forbes India).

I appreciate what technology and energy do to give us a comfortable life. Similarly, I appreciate airplanes, which take me home in a matter of hours. However this does not mean that I am ready to board a Space Shuttle to see mom: they explode way too often. Same is nuclear power: there has to be a simpler way to boil water.

Beppe

Post a Comment